Introduction to Biofabrication

By offering alternatives to organ transplantation and tissue repair, tissue engineering and regenerative medicine have shown significant potential to transform healthcare. Traditional tissue engineering techniques, however, need help in producing intricate and valuable tissues that can easily meld with the human body. Here we have biofabrication, a novel strategy that has become the nexus of tissue engineering.

To build functional tissues and organs, biofabrication entails precisely constructing biological constructions, frequently employing a combination of cells, biomaterials, and bioactive chemicals. To promote development, differentiation, and regeneration, it is intended to imitate the milieu that cells and tissues experience naturally. This cutting-edge research can overcome conventional tissue engineering constraints, opening the door to personalized treatment and game-changing healthcare solutions.

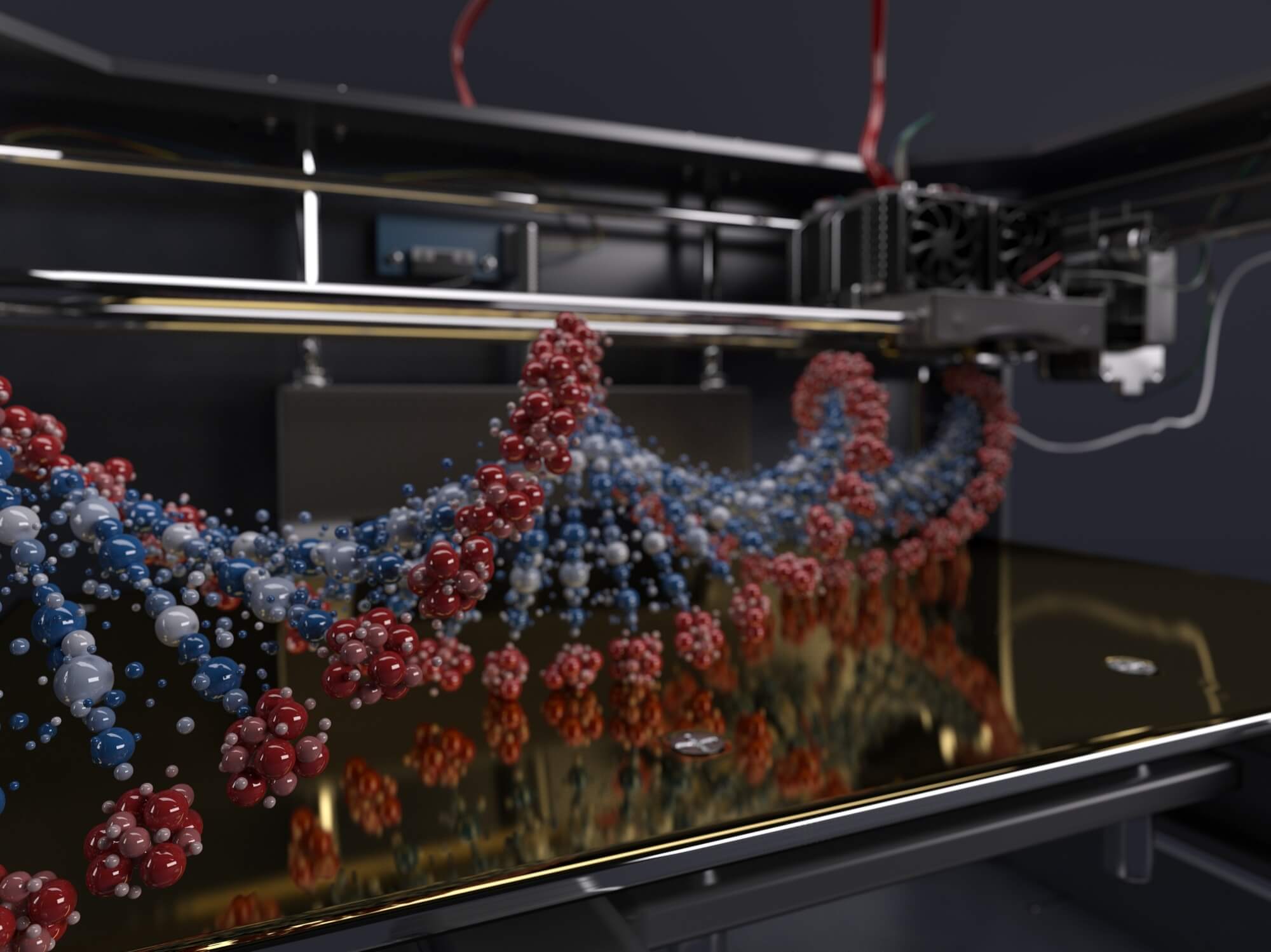

Understanding Biofabrication Techniques

Several biofabrication methods have been created to accurately and consistently produce complex tissues. 3D bioprinting, which enables the exact layer-by-layer deposition of living cells to develop three-dimensional tissue structures, is one of the most promising techniques. This method is comparable to standard 3D printing, but instead of using ordinary materials, it uses bioinks containing living cells.

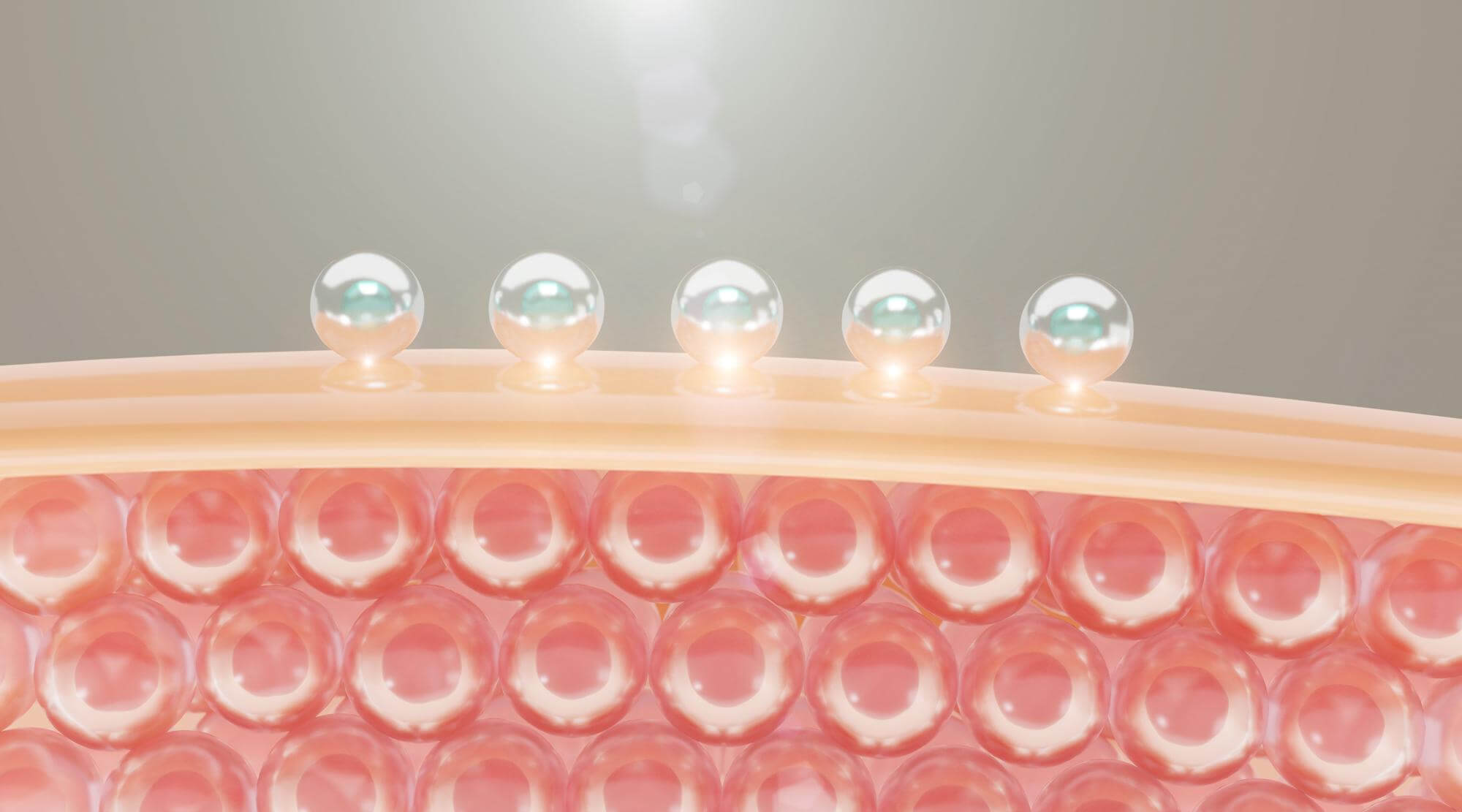

Electrospinning, which uses an electric field to spin biocompatible polymers into nanofibers, is another crucial method. These nanofibers create scaffolds that can help with tissue regeneration and cell development. The cellular components of an organ or tissue are also eliminated during the decellularization process, leaving behind an acellular structure that can be used as a template for tissue regeneration.

These methods can be used in various applications of tissue engineering and regenerative medicine since they have specific benefits and drawbacks. While electrospinning is the best method for producing scaffolds with a high surface area and porosity, 3D bioprinting excels at producing complicated structures. On the other hand, decellularization offers a natural extracellular matrix for tissue regeneration.

Biomaterials for Biofabrication

Biomaterials that offer mechanical support encourage cell adherence, and imitate the natural extracellular matrix are essential to the success of biofabrication processes. Typically, hydrogels or hydrogel-like substances with excellent biocompatibility and biodegradability are bioinks in 3D bioprinting. Most often utilized bioink components include alginate, collagen, hyaluronic acid, and gelatin.

The biomaterials used in electrospinning have a significant impact on the physical characteristics of the nanofibers. Electrospinning frequently employs polymers like polycaprolactone (PCL), polylactic acid (PLA), and polyethylene glycol (PEG), which have good mechanical strength and degrading properties.

Decellularization also necessitates the preservation of the vcrucial extracellular matrix proteins while removing cellular components using a combination of detergents and enzymes. Creating valuable tissues can then be accomplished by adding fresh cells to this acellular scaffold.

Improving biofabrication and the effectiveness of tissue engineering and regenerative medicine strategies depend on the ongoing development of biomaterials.

Applications of Biofabrication in Medicine

Biofabrication has a wide range of medical applications and shows great promise in solving pressing healthcare issues. Organ transplantation is one of the most important uses. The world is now experiencing a severe organ donor shortage, and biofabrication offers a viable answer. The danger of organ rejection is lessened, and the requirement for immunosuppressive medications can be decreased by using a patient’s cells to construct tailored organs.

Biofabricated skin substitutes have enormous potential for treating burns, chronic wounds, and other skin-related disorders in wound healing. These skin substitutes are more practical than conventional wound dressings because they encourage tissue regeneration, lessen scarring, and speed up wound healing.

Also, developing disease models for medication testing and research has benefited from using biofabricated tissues. Researchers can more properly test prospective treatment approaches and gain a better understanding of the illness mechanisms by simulating the physiological and pathological circumstances of certain diseases.

Challenges and Ethical Considerations

Biofabrication has a lot of potential, but there are still a lot of obstacles to overcome before it can be widely used in medicine. The biofabrication technique’ scalability is one major obstacle. Although scientists have successfully constructed microscopic tissue constructs in the lab, creating more extensive and complicated organs still proves challenging.

Moreover, the long-term survivability and performance of biofabricated tissues depend on the integration of blood vessels and neurons. A major obstacle in biofabrication is still achieving significant vascularization to meet bigger tissues’ nutrition and oxygen requirements.

The ethical ramifications of producing and using biofabricated tissues and organs should also be considered. As technology develops and biofabrication becomes more widespread, ethical issues around the procurement of organs, the sale of biofabricated organs, and the distribution of these life-saving therapies may arise.

Advancements and Future Prospects

Notwithstanding these difficulties, biofabrication has made great strides lately. New bioink materials are still being investigated, 3D bioprinting methods are being improved, and researchers are creating creative approaches to tissue vascularization. Progress in this area is being accelerated by partnerships between academic, industrial, and healthcare organizations. These partnerships have sped up the transition of biofabrication technologies from the lab to the clinic.

Biofabrication has the potential to revolutionize regenerative medicine in the future. Thanks to developments in personalized medicine, patients may have their tissues and organs biofabricated to match their biological traits. This strategy might result in more specialized and efficient therapies, lowering the possibility of patient rejection and enhancing general patient outcomes.

Personalized Medicine and Biofabrication

Aiming to provide customized medical care based on a person’s genetic make-up, lifestyle, and other unique aspects, personalized medicine strives to address these issues. This goal can be mainly realized thanks to biofabrication, which makes it possible to create customized tissues and organs. Bioengineers can create customized tissues from a patient’s cells, reducing the chance of rejection and improving the overall effectiveness of medical procedures.

For instance, a patient who needs a new kidney could create a kidney scaffold using their cells thanks to biofabrication. Upon transplantation back into the patient, the biofabricated kidney would no longer require immunosuppressive medications, increasing the patient’s quality of life.

Embracing the Biofabrication Revolution

Finally, biofabrication is the newest development in tissue engineering and regenerative medicine. This cutting-edge technology holds great potential for overcoming the drawbacks of conventional tissue engineering techniques and tackling pressing healthcare issues like organ transplantation and wound healing.

We are approaching a time when biofabricated tissues and organs are a standard medical treatment option as researchers continue to make strides in biofabrication methods and biomaterials. Biofabrication is a crucial field that necessitates ongoing research, collaboration, and funding due to its potential to tailor medical treatments, shorten waiting lists for organ transplants, and enhance patient outcomes.

There may be many difficulties regarding widespread clinical adoption, such as ethical issues and practical limitations. Yet, we can fully embrace the biofabrication revolution and usher in a new era of regenerative medicine in which scientists, engineers, policymakers, and healthcare practitioners work together.